Who we are

1919 – 1969

In 1919, following a merger with the Bromilow family, the company became Bromilow & Edwards, combining engineering expertise with transport innovation. Over the following decades, the company developed a reputation for durability and engineering excellence, supplying hydraulic tipping systems across the UK and abroad.

By the mid-20th century, Bromilow & Edwards had become widely known by the shortened brand name Edbro — a blend of EDward BROthers. The name was formally adopted as the business continued to expand globally, leading innovation in hydraulic tipping gear for the construction, waste, and bulk transport industries.

1996 – Today

Today, Edbro is a global leader in manufacturing hydraulic cylinder tipping systems, offering a full range of front-end, underbody, and custom solutions for rigid trucks and trailers from our 220,000 sqft facility in Bolton. We design, manufacture and supply hydraulic cylinder solutions to our global customer base for both on-road and off-road applications.

A passion for R&D

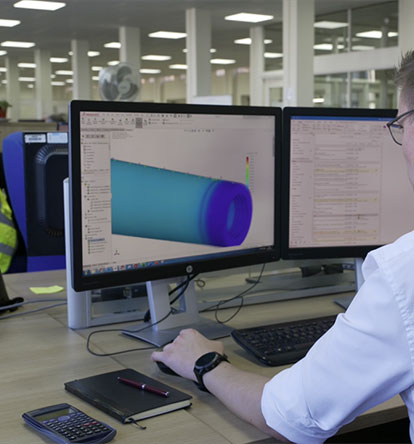

Our commitment to leading the way in hydraulic cylinder innovation remains as true as ever today, thanks to our talented in-house design team and commitment to Research & Development. This has allowed us to develop the lightest telescopic cylinder on the market.

Our development and test facilities include a wide range of test rigs, from endurance tipping, cyclic pressure, and fatigue testing facilities to static test rigs, allowing us to replicate many of the loading conditions our cylinders experience in the field.

From CAD and CAM design to FEA and testing, our team is constantly striving to develop the next pioneering Edbro innovation we can present to the industry.

Manufacturing excellence

From design to production, working with high tensile steel tubes sourced from proven mills across Europe and the USA, we combine our proud legacy of manufacturing excellence with some of the most comprehensive and advanced manufacturing facilities in the world.

This includes:

- A 3-stage fully automated cutting, boring and cleaning process – critical for hydraulic cleanliness.

- Extensive CNC machining capabilities to the highest standards of tolerance precision for thick-walled large diameter tubes through to precision piece part components.

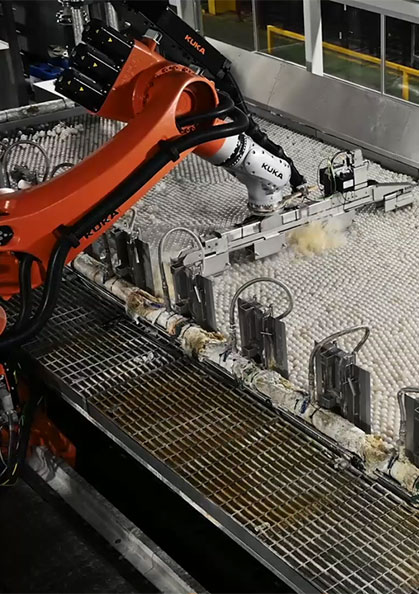

- Our vast welding capabilities include skilled manual, mechanised, submerged metal arc and laser welding. Our advanced robotic laser welding process has enabled us to manufacture the lightest telescopic cylinder on the market.

- Grinding and polishing; honing, skiving, burnishing and in-house chrome plating.

- In-house paint facility

WHY US?

Customer Support

All Edbro products are designed and built to optimise customer benefits.

- Lightweight equipment increases operator payload and profitability.

- The Edbro “fit & forget” promise minimises downtime and increases product durability for extra productivity.

- The extensive network of specialist spare parts and service agents provides after-sales peace of mind worldwide.

- Safety comes first in the design of Edbro products, ensuring an optimised working environment with reduced risk of accidents.